Wind Tunnel Instrumentation

Accurate and reliable signal conditioning for wind tunnel applications

Researchers use wind tunnels to study how objects are affected by airflow direction and by various pressures and forces. Wind tunnels host a wide variety of aerodynamic and acoustic tests, including propulsion systems, free flight, flutter, buffet, aero acoustics, and tests that involve real-time control, such as flutter suppression. Sensors used may include strain gages, pressure sensors, accelerometers, anemometers, balances, and more.

Wind tunnel tests may be steady-state, such as flow measurements, or highly transient, such as flutter, buffet, and aero-acoustic measurements. So the measurement system transfer function must be adaptable to a transient or steady-state test requirement and outstanding AC and DC accuracy are required. Measurement of unsteady pressure can require bandwidth exceeding 200 kHz, while model balances require precise DC accuracy of better than 0.01%.

An F/A-18 E/F model tested in NASA Langley Research Center’s Transonic Dynamics Tunnel (TDT).

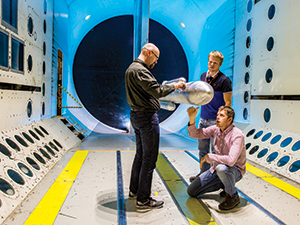

Final preparations are made on a model of the world’s most powerful rocket, the SLS, just before testing it in the TDT at NASA’s Langley Research Center in Hampton, Virginia. Credits: NASA/David C. Bowman.

Pressure sensors exhibit resonant responses that can limit usable sensor bandwidth for high-speed wind tunnel measurements. Precision Filters, in collaboration with Kulite Semiconductor Products, developed the patent pending REZCOMP™ technology to extend the frequency response of pressure sensors, accelerometers, microphones, and other resonant sensors in real time—with no need for post-processing. The application of REZCOMP technology typically extends usable sensor bandwidth by 200–300% or more.

Precision Filters’ 28000 system solves the challenges of wind tunnel testing. One signal conditioning card can support many different transducers. Our flat/pulse filter technology lets you select a frequency response characteristic—flat mode for frequency-domain analysis or pulse mode for time-domain applications. And our C-Series modules are fully compatible with National Instruments’ CompactRIO™ and CompactDAQ™ systems.

Because wind tunnel testing is expensive, it’s crucial to ensure accurate data: repeat testing due to a failure of the measurement system is not an option. Precision Filters' products have a series of automated sensor and cable health checks to give you confidence at test time. NIST-traceable calibration can be done on site, saving time and money, and the industry’s only automated “go/no-go” status report guarantees test performance.

Read on to learn more about the application of PFI technology to wind tunnel testing at NASA's Transonic Dynamics Tunnel.