Precision 28000 Test Subsystem

Test Subsystem for the 28000 Signal Conditioner

Performance verification is a critical part of ensuring data integrity of any measurement system.

A signal conditioner is a key component in the critical path of important test data, so its performance specifications must be rigorously proven and documented. At a minimum, yearly calibration helps to ensure defendable test data. But yearly calibration is costly, often requiring up to a month of downtime. And it's only the beginning. Making sure each channel works properly at test time means hours of tedious, difficult manual verification. The Precision 28000 self-test subsystem conducts rigorous yearly calibrations and quick Go/No-Go tests—all at the press of a button, and all without removing the system from the equipment rack.

Precision 28000 Test Subsystem

The 28000 test subsystem is a complete solution to performing both annual equipment calibrations and run-time performance verification. The 28000 test subsystem supports a suite of tests that run on the instrument right where it is, with no need to disassemble or move it. The tests check out all critical system specifications, are NIST traceable, and are the same manufacturing tests that are run at the factory.

Learn more about 28000 NIST Traceable Testing »

The 28000 test subsystem provides three levels of test. Pretest Verify and Diagnostics are used to confirm that all elements of the test subsystem are functional. The Factory Acceptance Test (FAT) performs a complete parametric performance check of the signal conditioners. Parameters such as common mode rejection ratio noise, offset, gain, frequency response, amplitude match, and phase match are tested to original specifications. The Go/No-Go test does a quick check of the current programmed setup prior to an actual test to provide documented proof of system performance.

The Precision 28000 Test Subsystem is a member of the Precision 28000 family of signal conditioners.

Learn more about the 28000 Signal Conditioning System »

28000 Test Subsystem Features:

- Fully automated Factory Acceptance Test for traceable periodic calibration)

- Built-in 28000 test hardware provides multiplexors, attenuators, detectors, and other functions needed for stand-alone test without the need for external switches and other specialized hardware.

- Go/No-Go test for pretest verification

- Third-party function generator and multimeter used for NIST traceability

- Intuitive graphical user interface

- Optimized for Ethernet operations

- Test multiple 28000 System

28000 Test Subsystem – Press of the Button Verification & Calibration

Benefits:

- Built-in test hardware and software let you leave the system in the rack and perform NIST-traceable calibration tests at the test site.

- Every card function is exercised and all data-critical performance characteristics are accurately measured and compared to published specifications as required for traceable, defendable annual calibrations.

- Detailed test data reports provide traceability and statement of test uncertainties.

- Go/No-Go test quickly verifies the settings of each channel prior to the test run.

- Reduce overall life cycle cost by reducing yearly calibration cost and system down time

28000 Test Subsystem Components

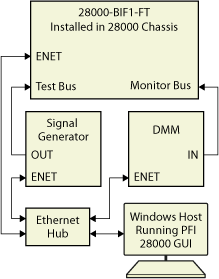

The test subsystem consists of the 28000 graphical user interface (GUI), the 28000-BIF2-FT backplane interface (BIF) card with option F installed, and the 28000-5-TEST third-party test instruments, along with 28000 signal conditioning card-specific cables and adapters.

- 28000-BIF2-FT Backplane Interface Card

- 28000 Graphical User Interface

- 28000-5-TEST Test Subsystem Instruments

| The 28000-BIF2-FT card (BIF) with option F is installed in each 28000 chassis. The BIF supplies control to 28000 signal conditioning cards and provides the necessary hardware to interface between the test subsystem instruments and the 28000 system internal test and monitor busses. |

28000 Test Subsystem |

| The GUI software running on the host computer controls the 28000-BIF2-FT backplane interface card and 28000-5-TEST test instruments. The GUI provides the necessary software modules to perform tests on all supported 28000 conditioner cards |

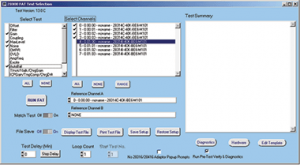

The FAT test selection panel allows the user to select any tests to run on any set of channels. Test results can be saved to a file for later retrieval. A test summary is listed for quick diagnosis. |

| The 28000-5-TEST test subsystem consists of third-party test instruments to provide signal sources and precise measurement capability. A Keysight 33509B function generator is used as the source of the test signals, and a Keysight 34465A precision multimeter provides measurement capability. In addition, the 28000-5-TEST includes a kit for side-by-side rack mounting and cables necessary to connect the instruments to the 28000 test and monitor busses. |

Keysight 33509B Function/Waveform Generator

Keysight 34465A High-Performance Multimeter |

Verification at Test Time

Continual setup, tear down and reconfiguring of sensitive test equipment demands a rigorous protocol to prove that every channel is operating correctly at test time. The 28000 System provides a layer of built-in verification and validation capability to confirm proper operation of the measurement system including sensor and cable. Upon completion of the verification testing, a status report is provided as a defendable means to document system validity at the time of the actual test.

Yearly Calibration

All test systems require periodic calibration. The Precision 28000’s automated built-in test capabilities allow the user to perform convenient, affordable NIST traceable yearly calibration tests on-site without removing the system from the equipment rack. This eliminates the need for expensive off-site calibrations and system downtime.